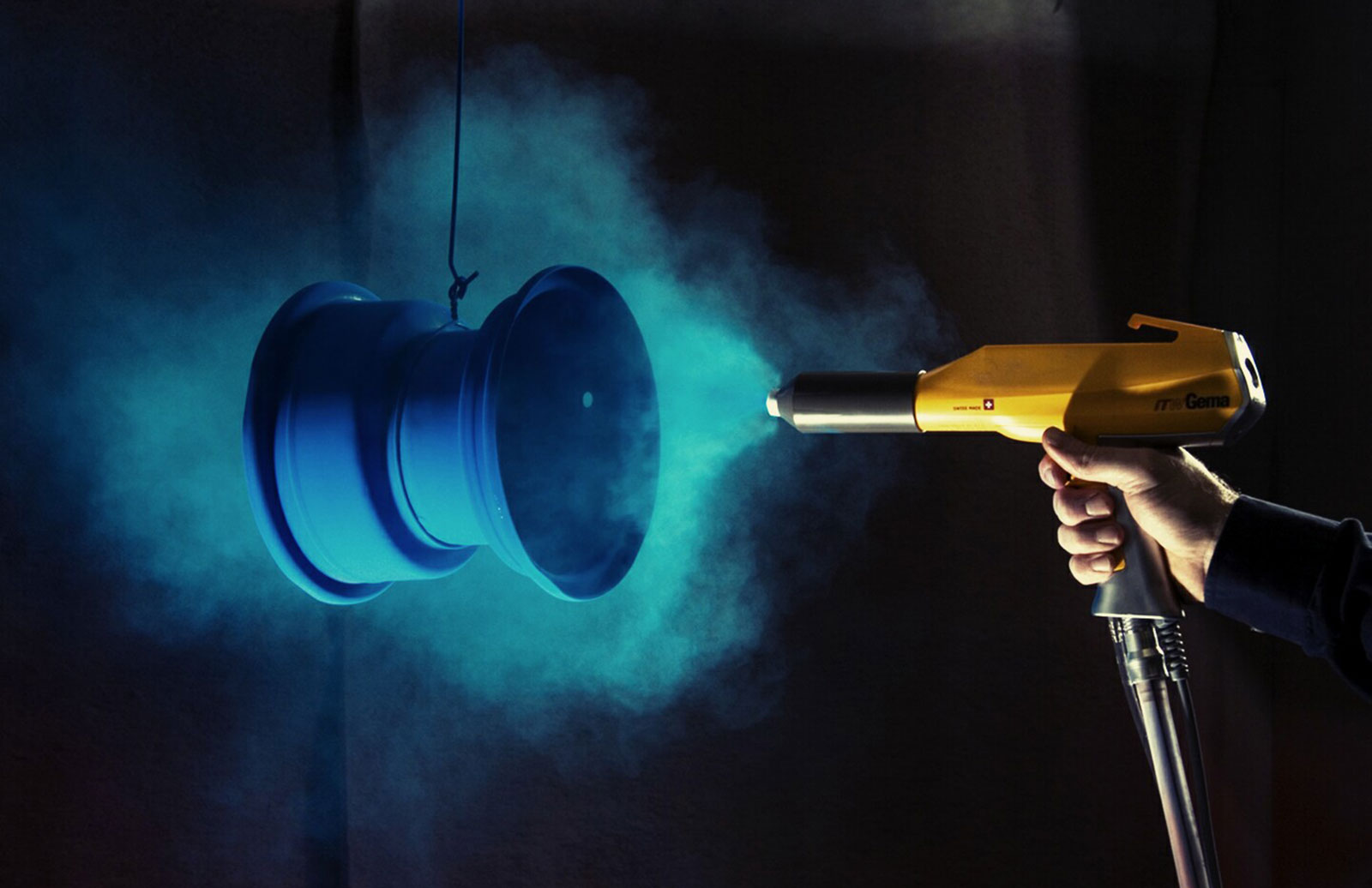

THE POWDERCOATING PROCESS

Powder coating is a process by which a coating of pigment is applied to the surface of an item to create a layer of color that is brighter, thicker and much tougher than conventional paint. It involves the use of a dry powder which is sprayed onto the cleaned surface of the item in question. The powder is held on by means of an electrostatic charge imparted to it by the specialized spray gun that is used. This powder is made of a special thermoset polymer, which responds to heat. When the powder is baked, it reacts with other chemical groups in the powder polymer and increases the molecular weight and improves the performance properties of the material, creating a smooth and uniform layer of pigment. This process is used primarily on metals because of the high temperatures that the powder must be cured at. One will most commonly see power coating on processed aluminum goods and appliances as well as automobile and motorcycle parts.

powdercoating services in central minnesota

Gull Lake Sandblasting and Powdercoating is your premier provider for sandblasting and powdercoating services throughout the Brainerd Lakes Area and central Minnesota.

what are the benefits?

There are advantages of powder coating over conventional liquid coatings. Besides being an efficient and environmentally compliant process, it produces a superior finish in extreme conditions, and decorative applications. Color selection is unlimited. Available in both high and low gloss, as well as textures - providing customers with a number of choices.

ECO-FRIENDLY

Powder coating is an environmentally friendly process unlike solvent-based wet paint systems. The powder coating process does not use solvents, eliminating dangerous VOC emissions. Being non-toxic it can be used on food service equipment and in its powder form is no more harmful than dust.

how long does it take?

Typically, in our shop, we have a 72 hour turn around time. The fact of the matter is that we have a wide range of customers with different deadlines. As the finisher, Gulllake Powdercoating is the last vendor to touch the product, but our work is the first thing the customer sees. Typically, given a date, we will meet the needs of our customers. This is how we have gained a solid reputation with our customers.

why is powder better than liquid?

Unlike liquid paint, powder coating is a dry process. Finely ground particles of pigment and resin are electro-statically charged by a specially designed gun that sprays powder to the electrically grounded part. This positively charged spray sticks efficiently and effectively. The part is media blasted, plugged and or sanded then hung on one of our racks. We then roll the rack into our powdercoating booth to be sprayed. In the final step, we push the rack into 1 of our 2 large curing ovens. The surface is then baked on permanently with 400 degree heat and then removed for cooling.

HOW MUCH WILL IT COST?

The cost of powder coating depends on many factors, such as size, weight, how it's going to be used, color, and most importantly the prep work required prior to coating. Masking, plugging, sanding, cleaning, blasting, plus any packaging needed for finished product are also factors that determine cost. Powders vary greatly in price from color, texture and quality including options like Ultra Durable and Architectural lines of powder that are available. We will discuss these important points to get you a quick and accurate estimate before doing any work.

COLOR OPTIONS

With thousands of powder colors and custom color-match services, Gulllake Powder Coating can help you choose the right color for your project. Our powders come from top powder coating manufacturers. We maintain a stock of powders for the most popular colors and finishes. As for the colors and finishes we do not keep on hand, these are readily available to us and can be onsite within a week. We are also happy to provide custom color matches when needed!